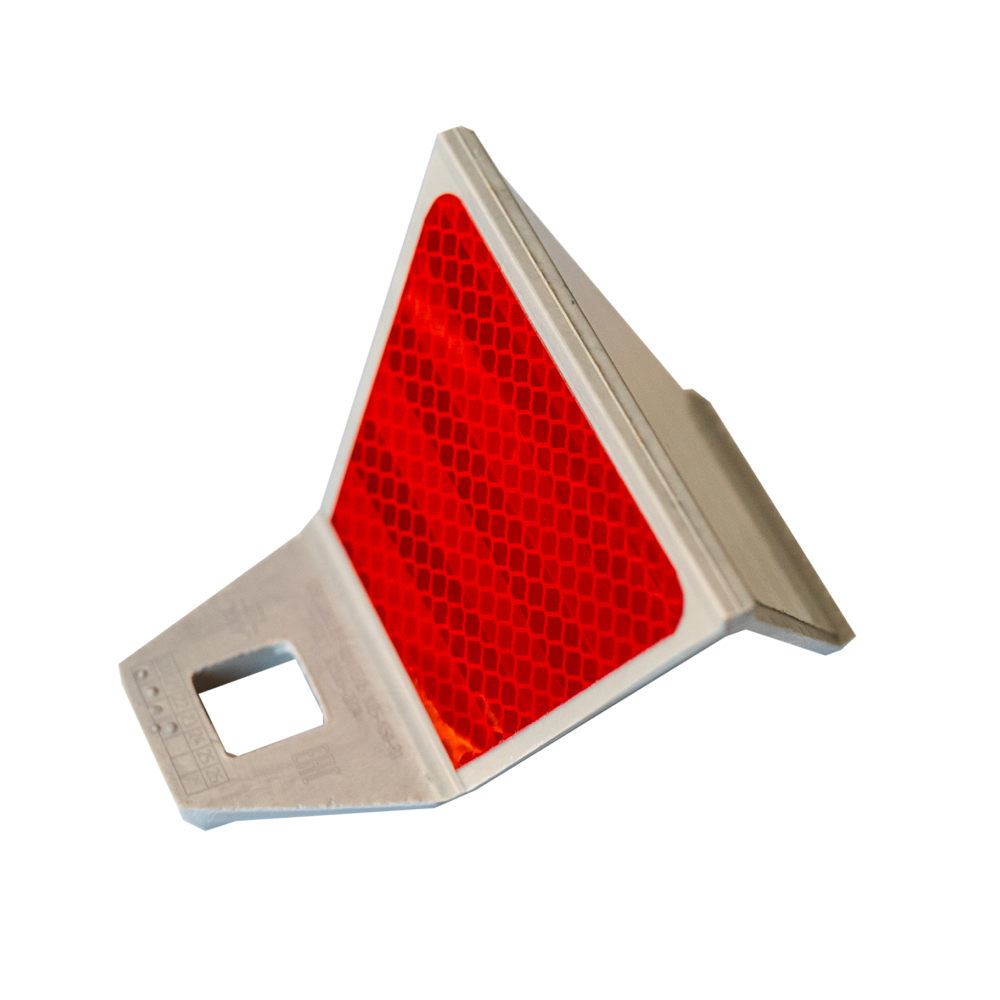

Intended to enhance visual orientation on road traffic sections and indicate the dimensions of the road during nighttime.

The composite reflector KD-5 by Zavod Prodmash consists of a monolithic composite casing, made by hot press moulding of glass fiber and polyester resin, as well as two reflective elements: red and white. Reflectors are installed on guardrails every 4 meters.

Materials and their characteristics:

The materials used for manufacturing KD-5 reflectors comply with the requirements of normative-technical documentation. The casing of the reflector is made using SMC technology from a high-quality composite material based on fiberglass and polyester resin.

KD-5 reflectors (cataphotes) are resistant to static exposure of liquids:

- Gasoline AI-95 according to GOST 2084 in accordance with GOST 32839;

- 3% aqueous and saturated sodium chloride (NaCl) solution at a temperature of (0±2)°C in accordance with GOST 12020;

- 10% solution of sodium hydroxide (NaOH) at a temperature of (20±2)°C in accordance with GOST 12020.

Determination of the durability of road reflectors to mechanical impact.

Determining the mechanical strength of KD-5 reflectors and the quality of their attachment to road infrastructure elements is performed through tenfold washing.

Preferably, at least three randomly selected test samples are installed on the road infrastructure elements 24 hours before the start of the tests in accordance with the rules of their application.

To conduct the tests, a power washing machine equipped with a brush with propylene bristles with a diameter of 600 to 900 mm is used. Brush rotation frequency ranged from 300 to 600 rpm.

Test

Technical parameters of the test:

Number of passes - 100 cycles Maximum brush operation mode - 30 minutes. Number of cycles - 50 approaches.

Results

- During 90 cycles, no detachment, abrasion, or other damage to the retro-reflective film was observed on both steel and composite casings. After 100 cycles, water penetration into the film structure was noticed within 1.5 mm from the edge perimeter, both on composite and steel casings.

- At this stage, three cycles of washing at maximum brush operation mode for 10 minutes were performed. The brush did not move along the samples; its axis coincided with the axis of one of the КД5-КБII-R1 reflectors. Due to the high-pressure water supply, neighboring КД5-КБII-R1 reflectors were also heavily wetted. As a result, the reflectors preserved their functionality completely. No damage or delamination of the film was observed. The marking label remained undamaged and readable.

- After 50 cycles, no significant changes were detected. The film remained undamaged, and no delamination was observed.

- There were no detachments or damage to the film.

* Photos and video materials of the test results are available upon request.

Compliance

- GOST 32866-2014 "Public Roads. Road reflectors. Technical requirements."

- STO 07525912-035-2019 "Composite road reflectors of KD-5"

- TR CU 014/2011 certificate.