Designed to prevent serious consequences of a collision of a vehicle with various engineering structures on the roads.

European standard EN 1317-3 was taken by the specialists of JSC "Prodmash Plant" as the regulatory document which specifies the use, testing and classification of crash cushions. This is due to the fact that most modern developments in the field of road construction are based on Western standards, as well as the absence of such regulatory bases in Russia.

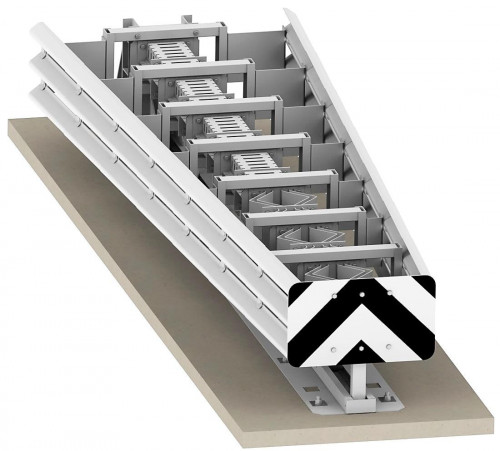

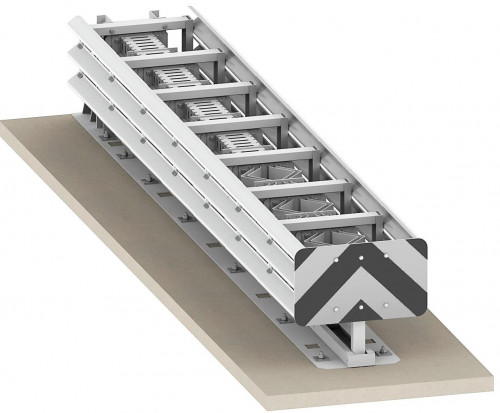

Different configurations are possible according to the customer's needs.

Installed at points of traffic flow separation before massive obstacles, bridge piers or tunnel supports and at other dangerous road sections, as well as tollbooths when the speed limit is 40 km/h. The use of crash cushion systems reduces the number of accidents with serious consequences and fatal outcomes. The crash cushion is mounted on the soil or onto a concrete canvas using chemical anchors.

The principle of the road crash cushion:

- Upon frontal impact to the attenuator, the vehicle pushes against a plate which moves the internal parts of the system, deforming them. The primary absorption upon impact occurs due to the deformation of the internal parts of the system.

- The deformation of the inner parts activates the outer beams, folding them telescopically.

The crash cushion produced by JSC "Zavod Prodmash" fully complies with the requirements of GOST 33128-2014 and GOST 33129-2014.

The attenuator's structures are patented and certified in accordance with the requirements of TR CU 014/2011.

The attenuator produced by JSC "Zavod Prodmash" has the following features: the production of the design is completely domestic; according to the customer's needs, different configurations are possible.

The structures were tested by the NAMI testing center at the Dmitrovskiy vehicle proving ground for crash attenuation from vehicles of various weights and at different speeds.